Rack Mounted Load Bank

380V/400V

50Hz/60Hz

3/4/6/15/18kW

1

Introduction

1. The simulated load equipment mainly has self-cooling, air cooling, water cooling and other heat dissipation modes. The water-cooled load uses liquid with high specific heat capacity instead of air as the refrigerant to dissipate heat for the heating power consumption components.

2. Compared with common air-cooled loads, water-cooled loads consume less power and make less noise. Water-cooled loads are suitable for data centers that require high energy consumption and silence.

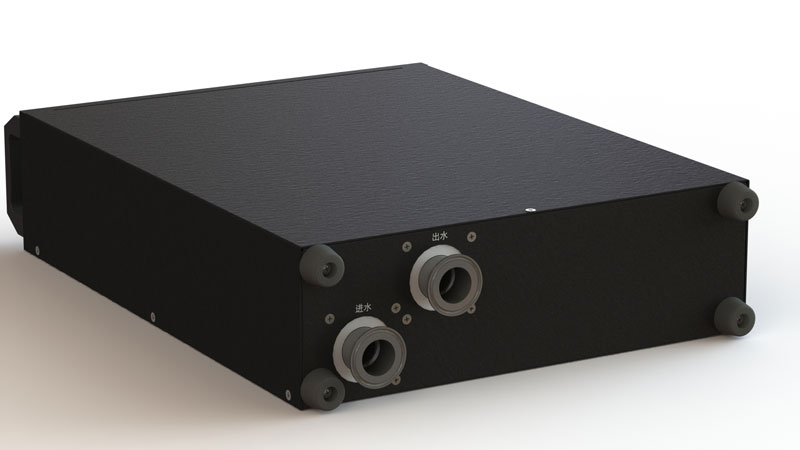

3.15kw, 18 kw rack liquid cooling load.

Main Features

Overview

The simulated load equipment mainly has self-cooling, air cooling, water cooling and other heat dissipation modes. The water-cooled load uses liquid with high specific heat capacity instead of air as the refrigerant to dissipate heat for the heating power consumption components.

Compared with common air-cooled loads, water-cooled loads consume less power and make less noise. Water-cooled loads are suitable for data centers that require high energy consumption and silence. Water-cooled loads can test, accept, and maintain key power supplies, such as power supplies, UPS, emergency power supplies, and generator sets in the equipment room.

Application field

The digital trend has led to a boom in the construction of data centers around the world. Because data centers are energy-intensive units, energy costs are a major expense for data centers. Currently, data centers around the world consume about 1.5 percent of the world's electricity each year. As a result, the demand for future data center energy efficiency indicators (PUEs) is increasing.

Google, Microsoft, Alibaba, Tencent and other global cloud computing giants are actively promoting the use of water cooling in data centers, so as to significantly reduce energy consumption. Water cooling of servers is becoming more and more obvious.

As important testing equipment in data center and network room, analog load device and rack-mounted dummy load can test, accept and perform routine maintenance on key power supply equipment such as power supply, UPS, emergency power supply and generator set in the room. On the one hand, it simulates power load to test the stability and reliability of power supply system; on the other hand, it simulates heat source to test the effect of refrigeration system.

With the water cooling of the data center, the load of the analog device also needs to be changed accordingly. The water cooled load can perfectly simulate the working state of the water cooled server, so as to scientifically evaluate and verify the power system and refrigeration system.

In addition to data centers, under the pressure of global energy conservation and emission reduction, many fields such as scientific research institutes, communication facilities, military equipment, aerospace, industrial enterprises, rail transit and so on have appeared the trend of water cooling to reduce consumption. Water cooling load can play an important role in these industries.

Comparative advantage

Simulated load device, rack type dummy load usually adopts air-cooled heat dissipation, compared with air-cooled, water-cooled load has the main advantages of:

※ Higher energy efficiency: water-cooled load can save 30%-50% of power consumption on average than air-cooled load.

※ Mute quality is better: at the same heat dissipation level, the noise of water-cooled load can be reduced by 20-35 decibels than that of air-cooled load.

※ Higher heat dissipation efficiency: the heat taken away by the same volume of liquid is nearly 3000 times that of the same volume of air, and the heat conduction capacity of liquid is 25 times that of air.

※ Stable performance and long life: Due to higher heat dissipation efficiency, the main component loss of water-cooled load is lower than that of air-cooled load, which can bring longer stable performance and service life.

Overall, water-cooled loads are more energy efficient, quiet, and reliable for users who value energy consumption and silence.

Technical Data

| General technical parameters (specifications and functions can be customized according to user requirements) | ||

| Specifications | AC380V-15kW | AC380V-18kW |

| Rated power

|

resistive load:total power 15kW

5 steps:1kW、2kW、2kW、5kW、5kW

|

resistive load:total power 18kW

5 steps:1kW、1kW、3kW、3kW、5kW、5kW

|

| Rated voltage | AC three-phase five-wire AC380V | |

| Frequency | 50Hz/60 Hz | |

| Special description | When the access is lower than the rated voltage, the power of the load cabinet stall changes according to Ohm's law | |

| Power factor | 1 | |

| The accuracy of each gear | Accuracy of each gear≤±5%,full load accuracy≤±3% | |

| Working mode | continuous working | |

| Electrical port | The input port is an industrial connector AC380V/32A | |

| Complete machine setting | Panel with power indicator light, fault alarm light

Optional LCD screen parameter display (including inlet and outlet water pressure, inlet and outlet water temperature, flow rate, tank temperature, etc.) and reserved calibration port

|

|

| Insulation class | F | |

| Protection level | IP24 | |

| Cooling method Liquid | water cooling

|

|

| The water inlet temperature | 5-50° | |

| Water flow rate | 1-5m3/h | |

| pressure | Liquid cooled vessel or resistor can withstand 6Bar working pressure, limit test pressure is 1.5 times working pressure | |

| modularization | The load is modular and can be used in a single module or in combination | |

| Volume | 431mm*176mm*550mm(width * height * depth) | |

| weight | ≤30kg | |

| Handling method | Lifting, forklift, flat push | |

| Operating temperature | -10℃~+70℃ | |

| Relative humidity | ≤95% | |

| Altitude | ≤2500米 | |

| Atmospheric pressure | 86~106kPa | |